Design Planning

We provide one-stop service, covering the whole process from design to delivery.

DTS develops customized plans based on your products, covering project details, time management, team collaboration and resource optimization, and provides full support and guidance.

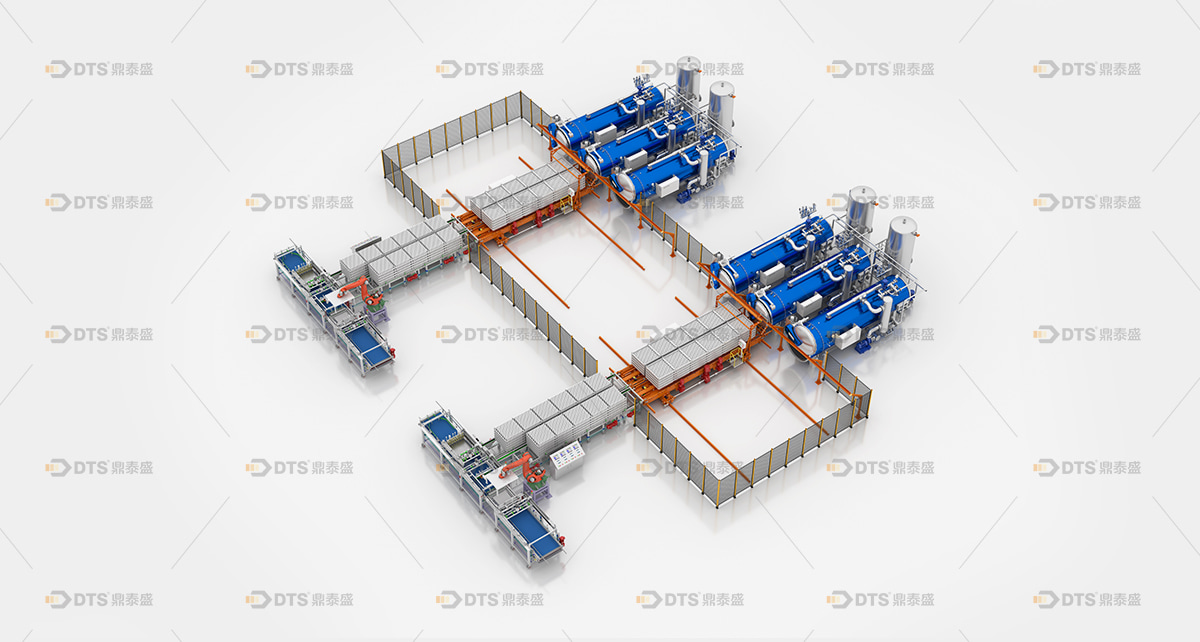

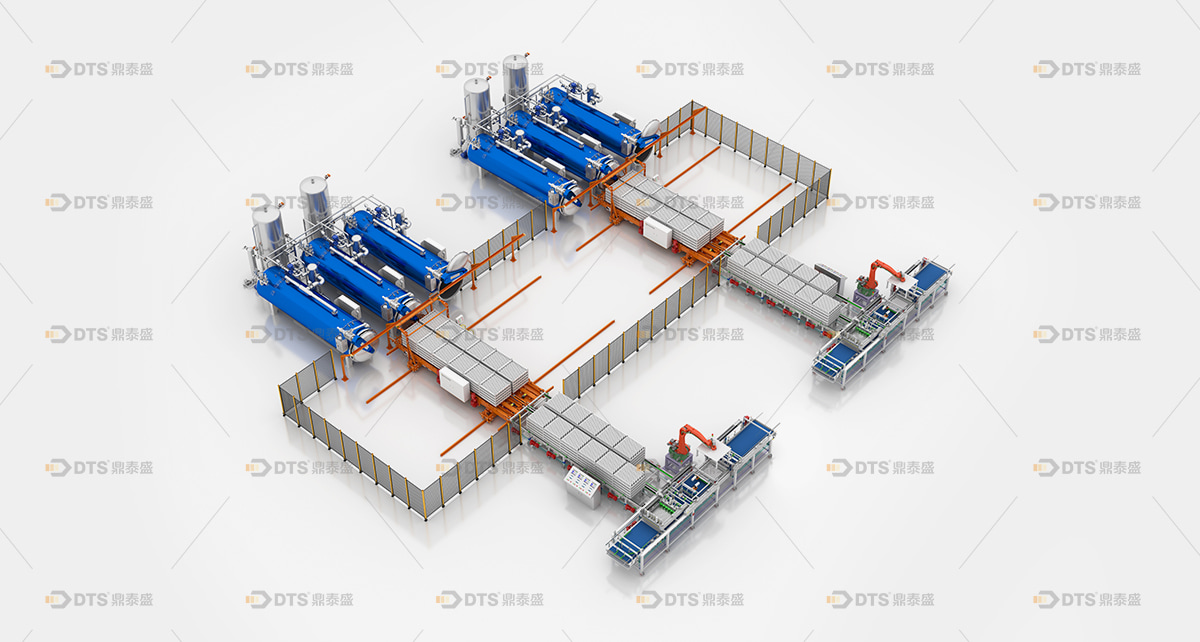

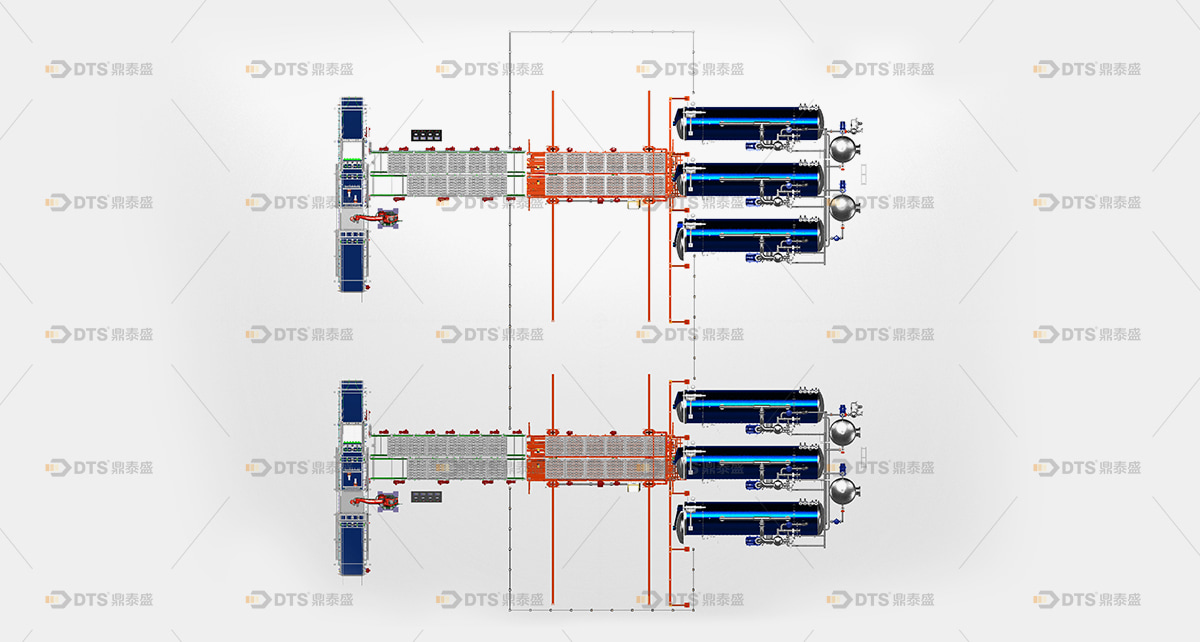

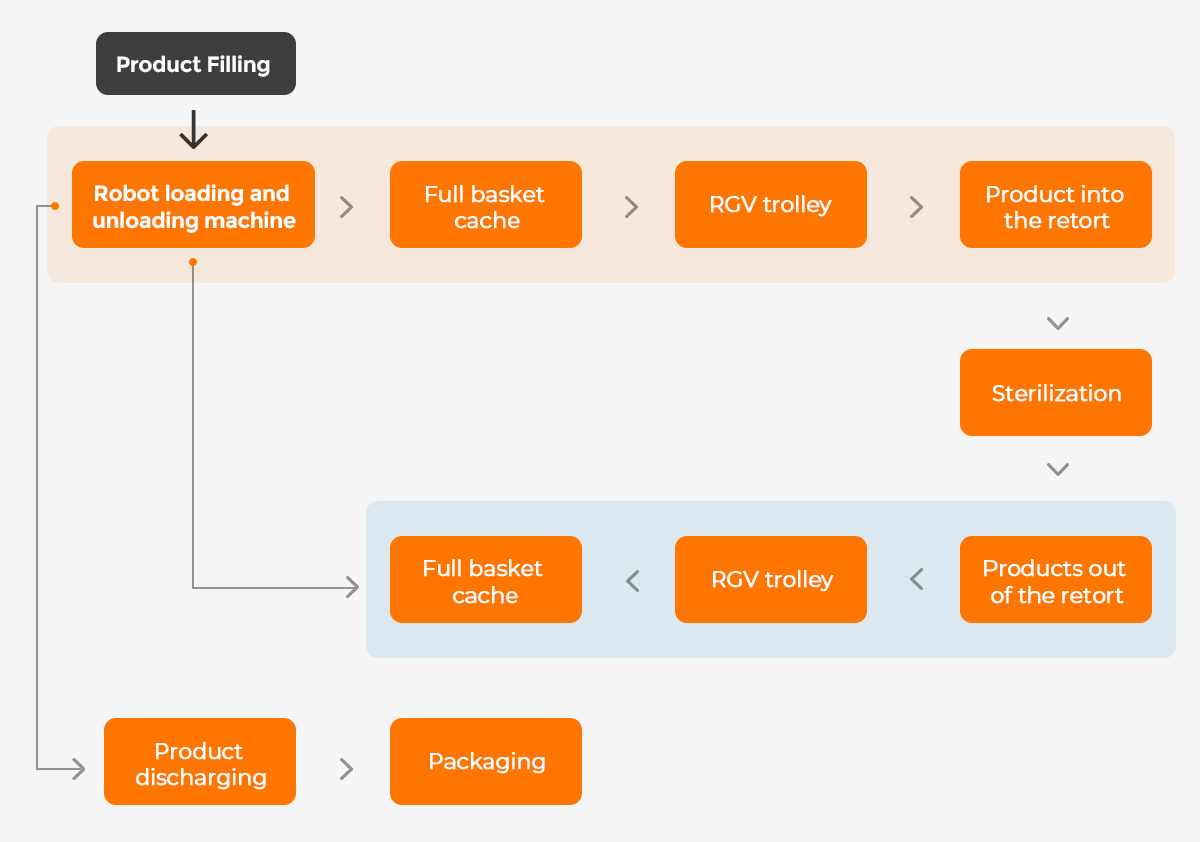

We can provide overall sterilization solutions for the food and beverage industry