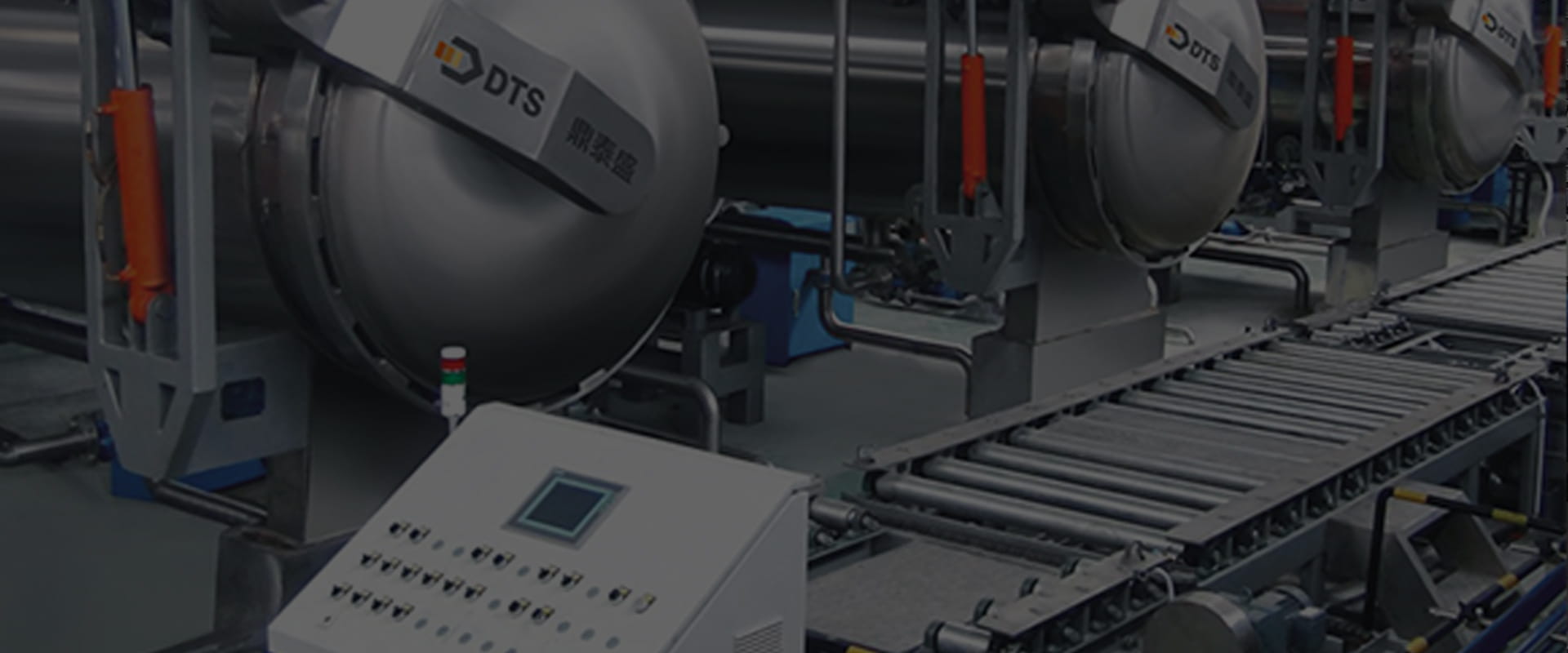

The DTS rotary retort introduces a rotation system to continuously rotate and stir the product 360° during the sterilization process, effectively promoting the uniform distribution and transfer of heat.

In addition to its advantages in processing large packages and high-viscosity products, DTS rotary retort is also suitable for sterilizing a variety of packaging forms and contents. Whether it is ready-to-eat meals, eight-treasure porridge, bird's nests, soy milk, evaporated milk and other products, this equipment can achieve rapid and comprehensive sterilization effects. This feature makes DTS rotary retort have broad application prospects in the food processing industry.

Why Choose DTS Rotary Retort Machine?

Equipment application scope

Unique design concept

Equipment stable performance

Compliant with HACCP and FDA/USDA certification

Equipment stability

Through its unique 360° rotation design, this function can perfectly cooperate with various sterilization processes and effectively meet the sterilization needs of high-viscosity ready-to-eat meals, porridge foods, evaporated milk, bird's nests and other products.

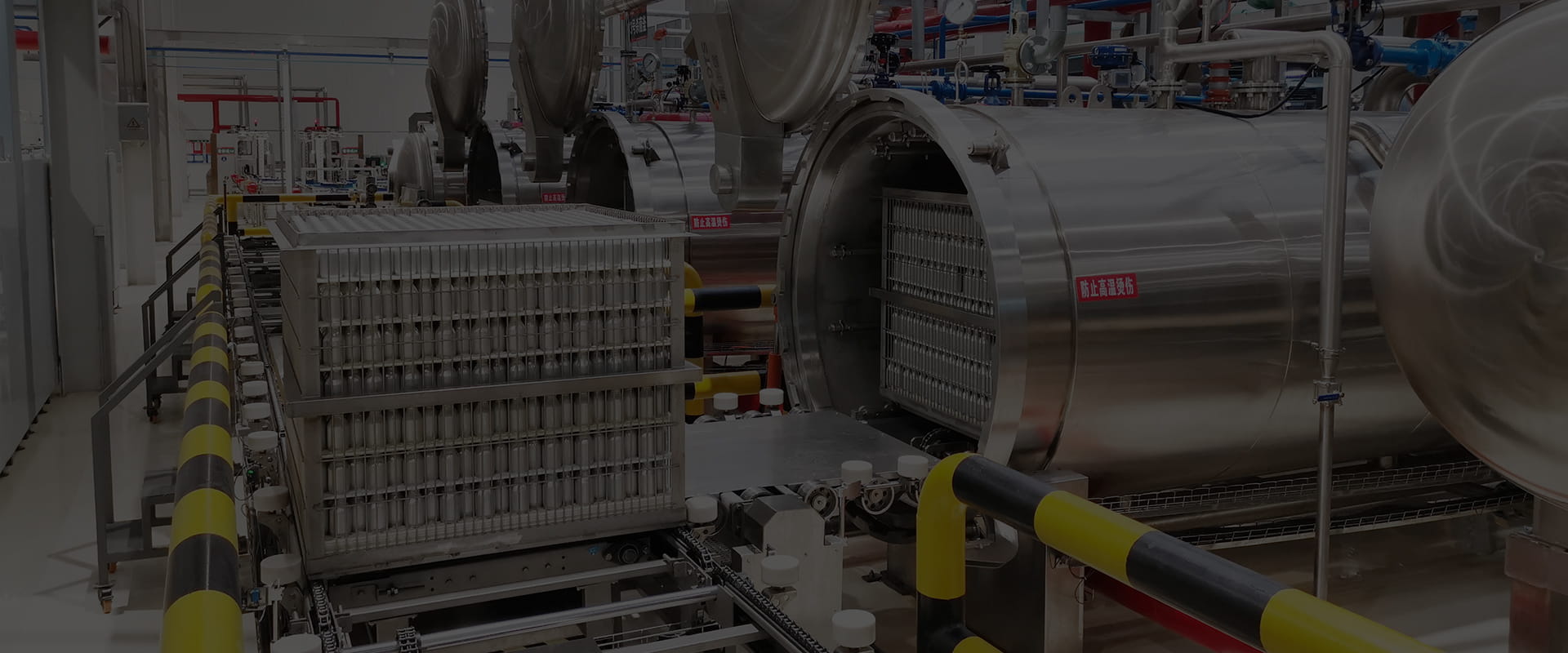

The spray rotary sterilization retort atomizes the process water through the nozzle and evenly covers the product surface. Using the high-speed circulation of atomized water and efficient heat transfer, the product can quickly reach the required heating temperature in a short time. Combined with flexible temperature and pressure control technology, it ensures the aesthetics and sterilization effect of the sterilized product. In addition, we use the spiral wound heat exchanger developed by DTS for indirect cooling to further improve the sterilization effect and product quality.

Steam rotary sterilization retort uses steam to directly heat products to achieve sterilization purposes. After the sterilization process is completed, cold water can be used to directly cool the product, or indirect cooling can be achieved through a heat exchanger. Both cooling methods can improve the cleanliness of sterilized products while optimizing the sterilization effect and quality.

The water immersion rotary sterilization retort completely immerses the product in water, and uses water as a sterilization medium to transfer heat to heat and sterilize the product. After sterilization, the hot water is recycled to the upper tank, and then cold water is added to lower the temperature of the product. This method ensures that the product is heated evenly during the sterilization process and can be cooled quickly and evenly after sterilization, thereby ensuring the stability and consistency of product quality.

After completing the sterilization process, the sterilization retort will automatically send out a completion signal. Only then can the retort door be opened and materials can be unloaded. In order to fully ensure the safety of the operation process, the retort is equipped with a four-fold safety interlocking mechanism to ensure that the retort door cannot be opened when there is still pressure in the retort.

Certificates

Our Commitment To Quality, Safety & Sustainability

Rotary Retort Machine

DTS rotary retort is an efficient, rapid and uniform sterilization method

View This Machine

Quality Assurance

R&D Capability

After-sales Service

FAQ of DTS Rotary Retort Machine

- I am interested in your product, could you please send catalogue or website to me?

Our company has 24 year experience, and customers spread to 45 countries, cooperated with Nestle, Mars, Bonduelle, Budweiser, Dole, Shineway and other group companies. For knowing more about DTS, please kindly check attached our catalogue and presentation.

- How long about the process time?

Normally this should be provided from your side, but according to our experience, it’s around 60min.

- Which kind retort is suitable for our product?

Could you please tell me your product, packaging, packaging size and other basic information? And did you used retort before?

- How much steam, water will consume for this retort?

I will send you the utility consumption in the proposal.

- Your competitors offer us 7 days of free installation and debugging, can you provide it too?

Yes, we can provide 7 days of free installation and debugging(different customers need specific analysis).

- How long is the delivery time? Can it be shortened?

Could you please tell me when do you plan to use the machine? Is it urgent or not? Normally we require 4 months, but if it’s urgent for you, I will talk with our production manager

- What is your after sale service?

Our service team consists of 20 engineers can provide customers with one-to-one timely and effective 7*24 remote online services. Providing training services for customers personnel to DTS. We have agencies in 16 countries.

- Do you have any local service?

Yes, we can provide the before and after sale service in your country. If you need any more information about the machine, you can contact them or me, we will do our best to meet your needs.