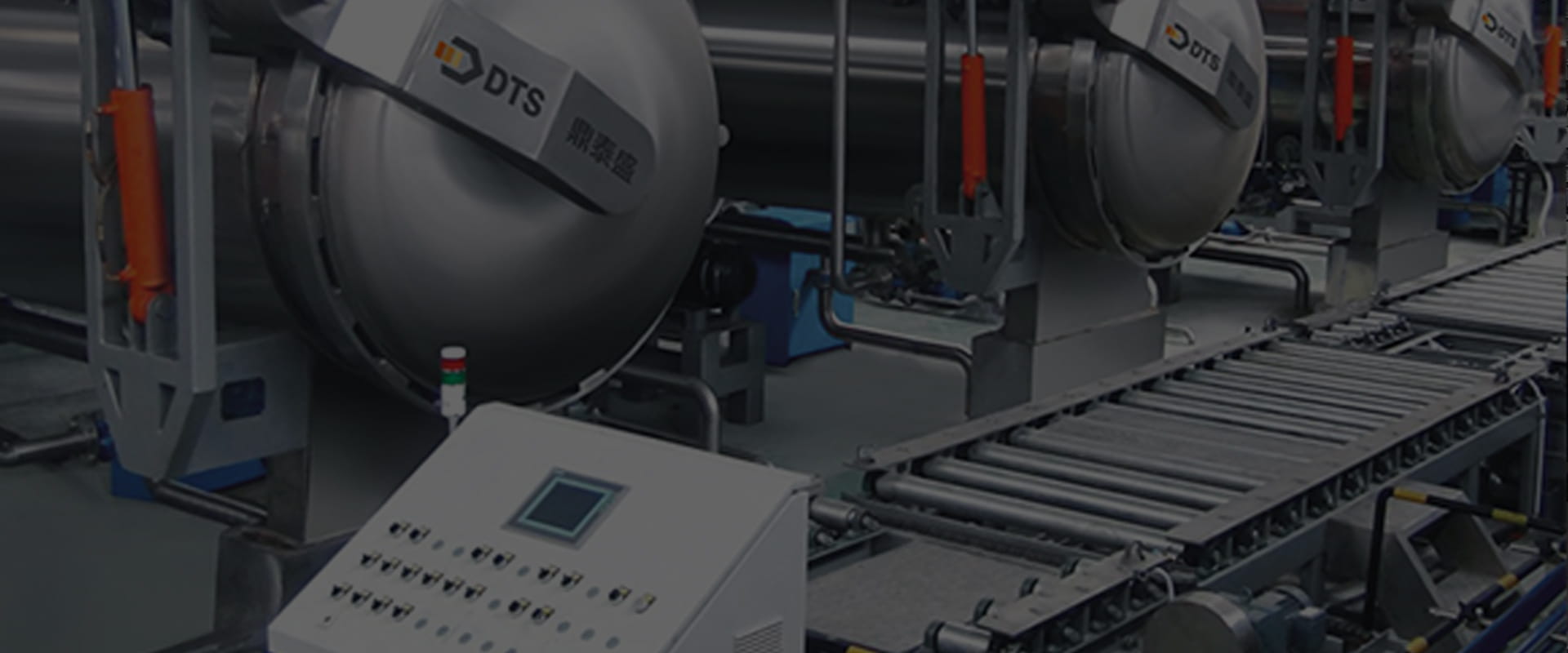

Why Choose DTS Water Immersion Retort Machine?

Balanced flow distribution

High temperature and short time treatment

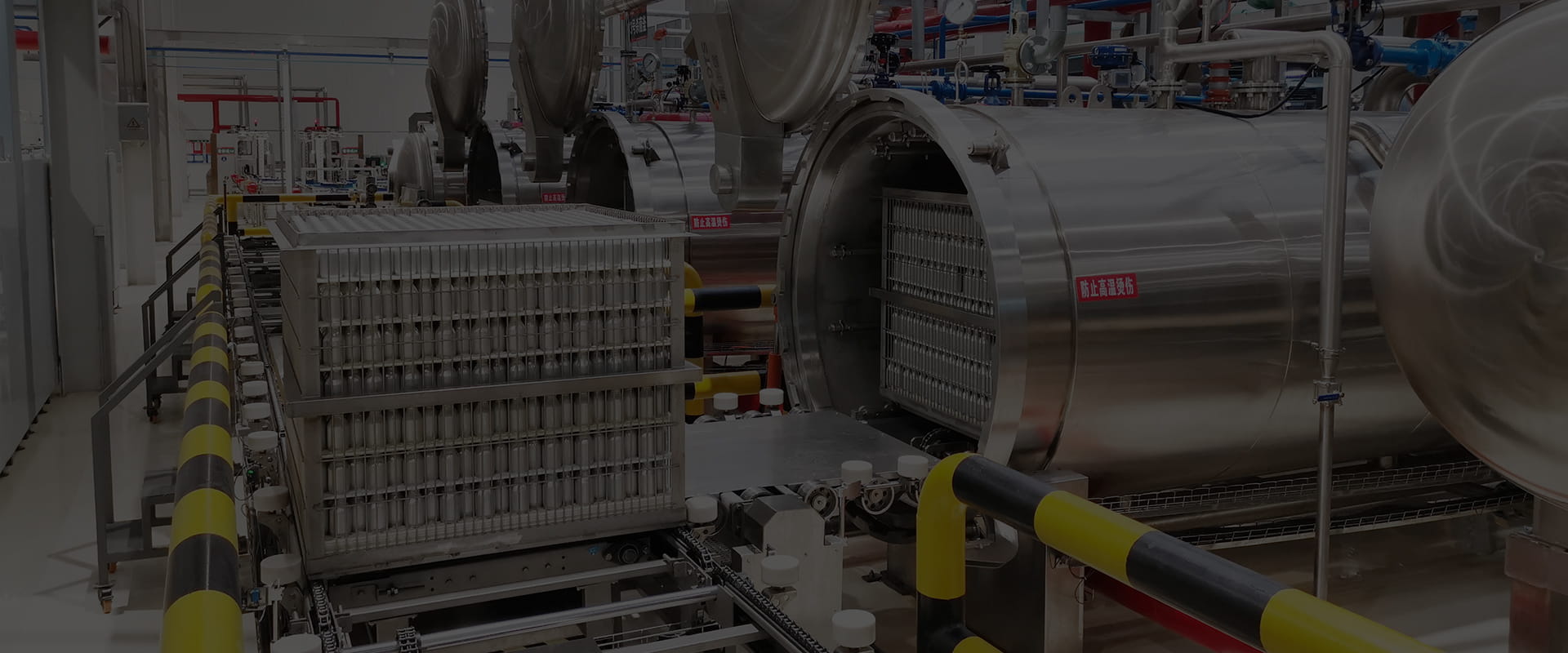

Suitable for easily deformable containers

Suitable for handling large packaged foods

Compliant with HACCP and FDA/USDA certification

High quality design and production

The sterilization process is carried out automatically according to the entered microprocessor controller (PLC) recipe.

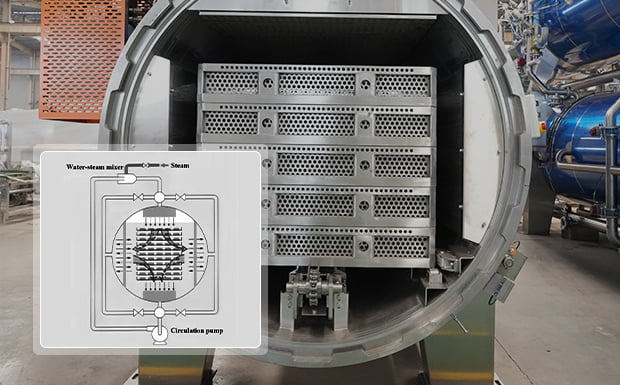

In the initial stage, high-temperature hot water is injected into the sterilization retort from the hot water tank. The hot water is then mixed with the product and continuously circulated through high-flow water pumps and scientific water distribution pipes. Steam is injected through the water-steam mixer to continue heating and sterilizing the product.

The liquid flow switching device configured in the sterilization retort ensures uniform water flow distribution in any vertical or horizontal position by switching the direction of the water flow in the process tank. This property is essential for achieving excellent heat distribution, thus ensuring an efficient and stable sterilization process.

During the entire operation of the sterilization retort, its internal pressure is accurately controlled by the automatic valve through the program to realize the input and discharge of compressed air. In view of the water immersion sterilization method, the pressure in the retort is not directly related to the temperature. Therefore, we can flexibly set the pressure in the retort according to the needs of various product packaging to ensure that the equipment can meet diverse application scenarios, such as flexible packaging bags and plastic bottles, plastic cups, plastic bowls, etc.

In the cooling stage, hot water recovery and replacement can be selected to recover sterilizing hot water into the hot water tank, thereby saving heat energy.

Certificates

Our Commitment To Quality, Safety & Sustainability

Water Immersion Retort Machine

DTS water immersion sterilization retort is a device that achieves efficient, fast and uniform sterilization...

View This Machine

Quality Assurance

R&D Capability

After-sales Service

FAQ of DTS Water Immersion Retort Machine

- I am interested in your product, could you please send catalogue or website to me?

Our company has 24 year experience, and customers spread to 45 countries, cooperated with Nestle, Mars, Bonduelle, Budweiser, Dole, Shineway and other group companies. For knowing more about DTS, please kindly check attached our catalogue and presentation.

- How long about the process time?

Normally this should be provided from your side, but according to our experience, it’s around 60min.

- Which kind retort is suitable for our product?

Could you please tell me your product, packaging, packaging size and other basic information? And did you used retort before?

- How much steam, water will consume for this retort?

I will send you the utility consumption in the proposal.

- Your competitors offer us 7 days of free installation and debugging, can you provide it too?

Yes, we can provide 7 days of free installation and debugging(different customers need specific analysis).

- How long is the delivery time? Can it be shortened?

Could you please tell me when do you plan to use the machine? Is it urgent or not? Normally we require 4 months, but if it’s urgent for you, I will talk with our production manager

- What is your after sale service?

Our service team consists of 20 engineers can provide customers with one-to-one timely and effective 7*24 remote online services. Providing training services for customers personnel to DTS. We have agencies in 16 countries.

- Do you have any local service?

Yes, we can provide the before and after sale service in your country. If you need any more information about the machine, you can contact them or me, we will do our best to meet your needs.